Analysis

Phase

This is the most important phase, when the idea meets the experience of Magic’s people. We analyse all the possible technical solutions based on the required needs.

Design

Phase

A future plan is created. From the idea to the design. Tailor made solutions to suit customer’s needs.

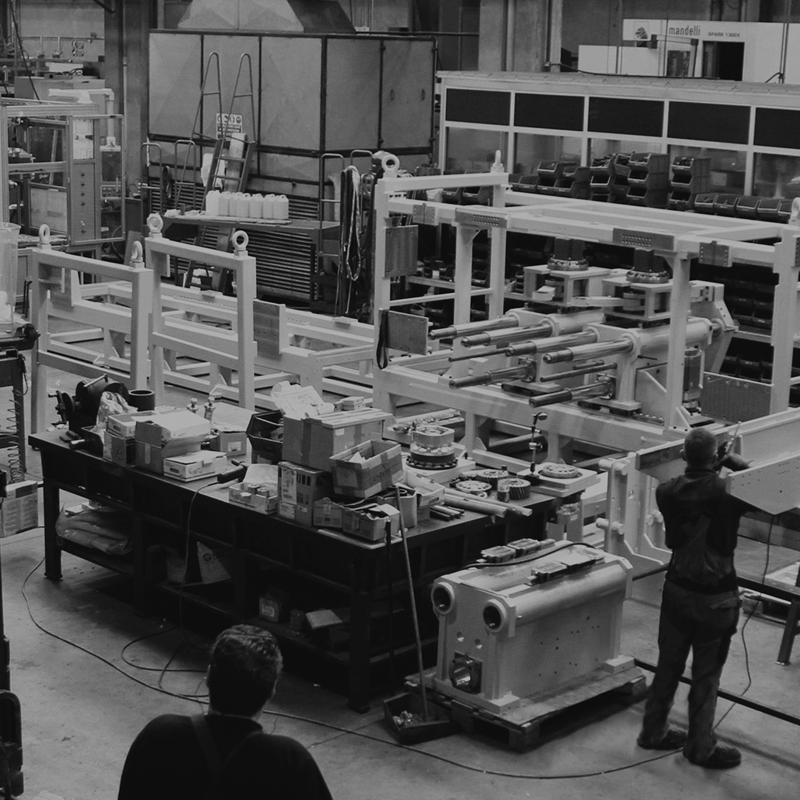

Production

Phase

Everything is designed and manufactured internally in order to have complete control of the process.

Testing

phase

Commissioning

phase

Strict procedures to check the proper operation of the machine.

Final checks to grant that machine operation complies with customer’s needs.

Quality has always been our priority and this is why we have a product qualification process

Any internal or external product follows a material verification process.

Each component is subject to stress testing to guarantee long life.

Dedicated treatments for the durability of a product, use of long lasting materials.

Success

Completed projects for the development of recycled material

Capabilities

Capabilities to build high production of machines

Service & Spare Parts

MAGIC MP spa

HEADQUARTER

Via Puecher 24, 20842 Besana

In Brianza MB

Tel. +39 0392301096

customercare@magicmp.it

REGISTERED OFFICE

Via Marengo 22 - 20841 Carate Brianza (MB) ITALIA

C.F. e n.iscr. al Registro Imprese: 00852330158

P.I. 00697440964

Capitale sociale: 600.000,00 €

Società per azioni con socio unico

REA: MB - 6909909

© 2021 MAGIC MP spa

Proudly designed by CREAMA